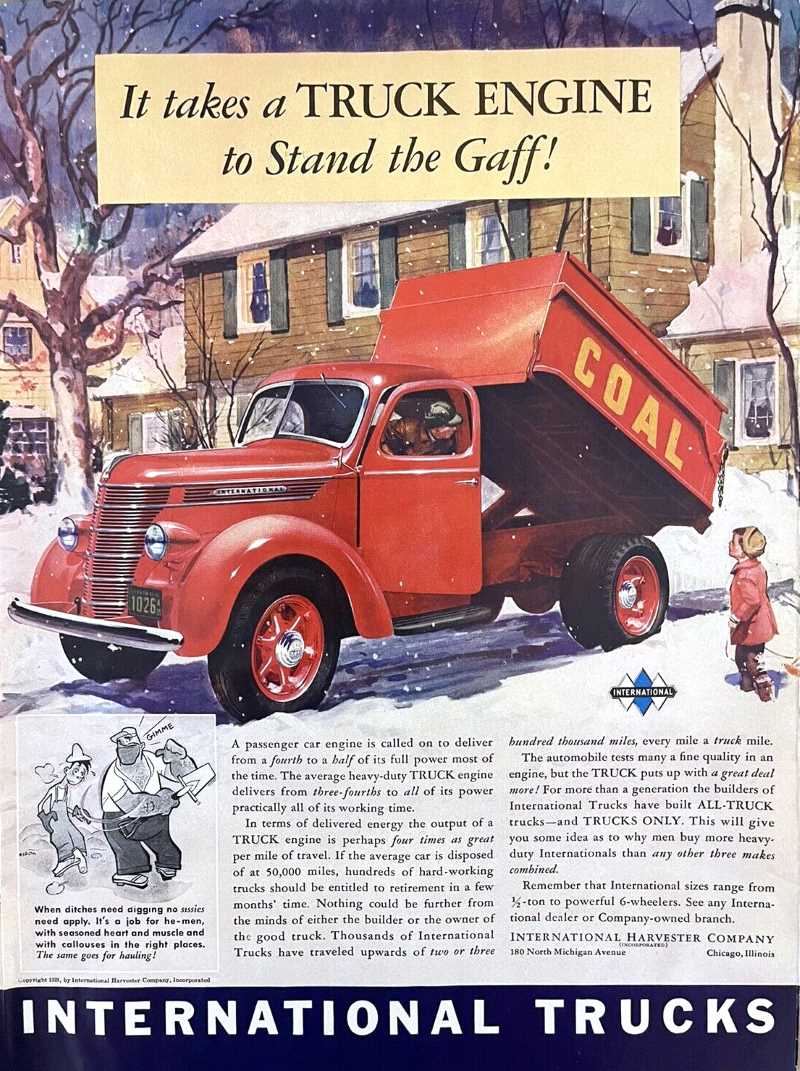

When the temperatures drop these days, staying warm is as simple as turning up the thermostat, but back in the early to mid-20th century, it wasn’t so simple. Keeping cozy at home meant having a steady supply of coal on hand—and that’s where the coal delivery process began. Before motorized trucks took the job, horse-drawn carts clattered down icy streets with workers lugging 100-pound sacks of coal to fill basement bins. With coal heating nearly 55% of U.S. homes by 1940, demand surged, and as technology advanced, so did the process. Soon the streets echoed with the rumble of coal trucks, built tough to handle heavy loads and unforgiving weather.

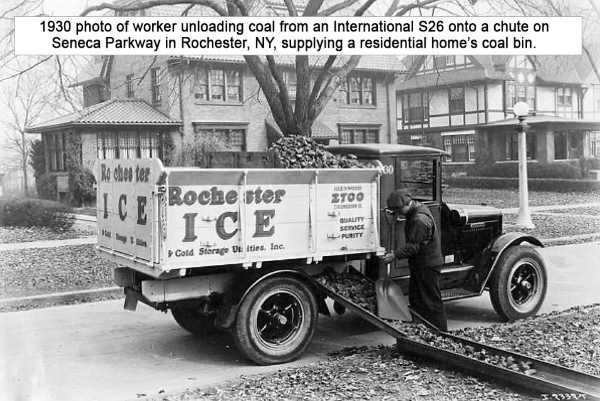

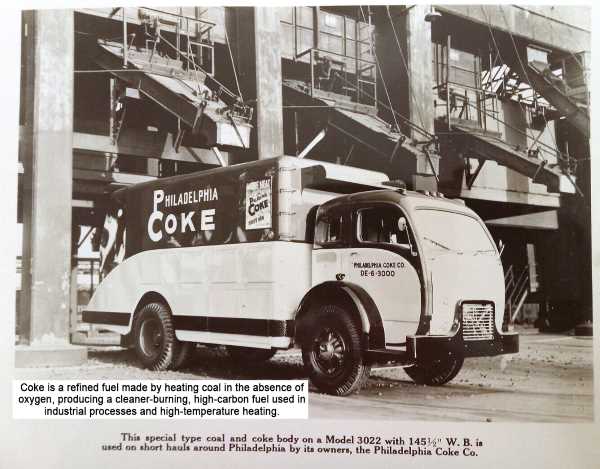

Coal delivery wasn’t glamorous, but it was essential, and the tools that took on the task were just as no-nonsense as the men using them. These weren’t just any methods—they were purpose-built, modified, and customized to handle the backbreaking demands of the job. Flatbeds, open-bodied rigs, and compartmentalized haulers all had a role to play, each one equipped to carry different grades of coal like nut, pea, and stoker coal. With chutes and conveyor systems mounted right on the truck, these machines made it easier—and cleaner—to funnel coal directly into basement storage bins. No more wheelbarrows full of black dust trundling down the driveway or dirty hands messing up mama's clean house.

Handling unforgiving weather required these trucks to be more than just durable—they needed specialized adaptations to keep them rolling through snow, ice, and freezing temperatures. Many coal delivery trucks were fitted with chain-driven axles, a hallmark of the Mack AC Series, which gave them the traction to climb steep, icy grades. For added grip, drivers would fit tire chains around the wheels, biting into snow and ice for extra traction. Some trucks, like the Mack AC, were specifically designed with high-clearance frames, allowing them to operate in deeper snow without getting bogged down.

In extreme cold, diesel engines could struggle to start, so many trucks were equipped with block heaters to keep engines warm overnight. This ensured that trucks could be ready to go at first light, even in subzero temperatures. Trucks with enclosed cabs offered drivers relief from the elements, as opposed to early open-cab designs. Later models like the International KB-5 and the Chevrolet AK Series came with enclosed cabs that shielded drivers from the worst of the weather. For better visibility during snowstorms, trucks were equipped with manual wiper blades or, later, air-powered wipers to keep windshields clear.

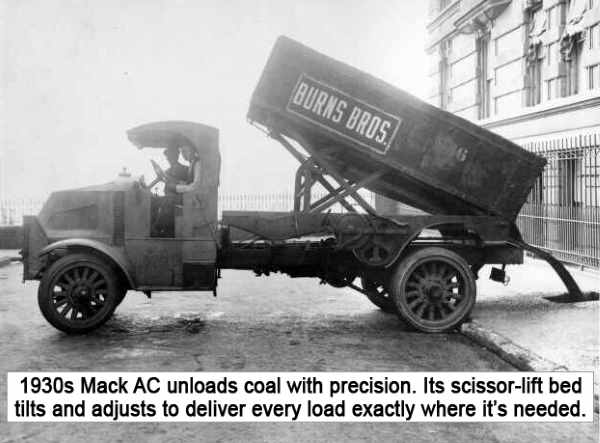

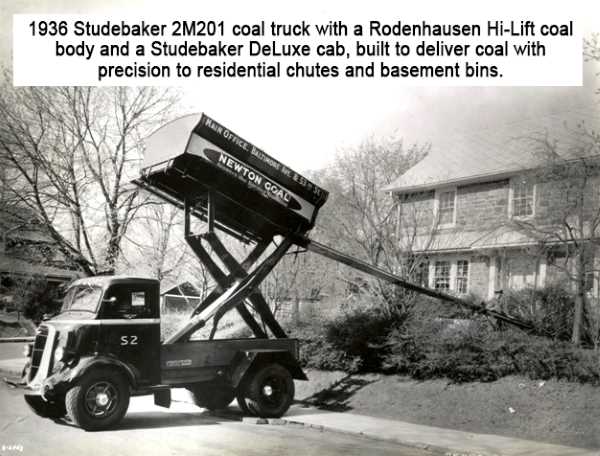

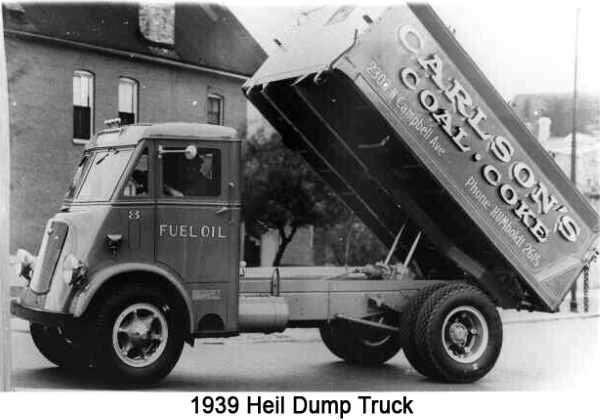

Innovations specific to coal delivery trucks made the task faster, safer, and more efficient. Early designs relied on workers to manually unload coal with shovels and wheelbarrows, but technological advancements eliminated much of that labor. Trucks like the International KB-5 featured hydraulic lift beds that could tilt the truck bed at an angle, allowing coal to slide down through chutes into basement coal bins. Scissor-lift beds provided even greater unloading control, letting drivers adjust the height and angle to get the coal precisely where it needed to go. Compartmentalized bins on certain trucks allowed for the delivery of multiple coal grades in a single trip, reducing the need for separate deliveries. Side-dump beds were another innovation, enabling faster unloading when direct chutes weren’t available.

Among the ranks of these workhorses, a few iconic models stood out. The 1948 International KB-5 was a powerhouse of muscle and efficiency. Built with a 'Hi-Lift' scissors-style mechanism, it could tilt the truck bed skyward, letting gravity do the hard part of unloading. L.S. Young & Sons in Denville, NJ, put their KB-5 to work from 1948 until 1987. With a powerful engine and hydraulic lift system, the KB-5 made short work of long delivery routes, unloading coal with ease.

The Ford Model AA, produced from 1927 to 1932, was the everyman’s truck—reliable, sturdy, and simple to maintain. It’s no wonder so many smaller coal operations relied on them. Able to haul hefty loads and navigate tight city streets, the Ford AA became a bread-and-butter machine for small-town coalmen. Its affordability and durability made it one of the most commonly used coal trucks of the era.

Then there was the Mack AC Series, the chain-driven legend of heavy-duty hauling. Debuting in 1916, the Mack AC’s chain-driven rear axle gave it the traction needed to pull heavy coal loads up steep, icy grades. This rugged beast was equally at home on city streets and industrial sites, earning a reputation for durability that still holds weight today among vintage truck collectors.

The Diamond T Model 201, often called the "Cadillac of Trucks," was as stylish as it was strong. Built from 1938 to 1949, it became known for its craftsmanship and smooth handling. But don’t let its sleek design fool you—this truck could handle serious weight. Coal companies prized the 201’s versatility, using it to haul coal, building supplies, and anything else that needed transporting.

The Chevrolet AK Series, produced from 1941 to 1947, proved that even a mid-size truck could play with the big boys. Practical, reliable, and tough, the AK’s compact design made it perfect for navigating narrow urban streets where bulkier trucks couldn’t fit. Its popularity during wartime production meant it became a familiar sight on delivery routes across the country.

These trucks weren’t just machines—they were lifelines. Their hydraulic lifts, chutes, and clever design features made it possible to keep homes warm through the coldest winters. And when heating oil and natural gas took over, these same trucks often found second lives delivering oil, gasoline, and diesel fuel. Their legacy lives on with collectors and vintage truck enthusiasts who see more than just steel and rubber—they see the muscle behind America’s warmest memories.